Ford F-150

Front Brake Pads Replacement Guide

How to change the front brake pads on a

12th generation 2009 to 2014 Ford F150 truck with photo illustrated steps.

By Paul B. Michaels Author & Photographer Auto Mechanic Since 1989 |

||

Ford F-150 Front Wheel |

Pry Off Lug Nut Cover |

Hub Cap Removed |

| This

automotive "how-to" guide was specifically written to assist owners

of the 12th generation (2009, 2010, 2011, 2012, 2013 & 2014) Ford F-150 truck

in changing the front disc brake pads. Owners of other F-Series trucks or other Ford, Lincoln and Mercury vehicles such as the Super Duty F-250, F-350, F-450, Expedition, Explorer, Edge, Escape, E-150, E-250, E-350, Transit Connect, Flex, MKX, MKT, Navigator and Mountaineer may also find these DIY front brake job instructions to be helpful. The tools needed to complete this procedure include a flathead screwdriver, lug nut wrench, floor jack, jack stands, 13mm socket, a 3/8" drive ratchet, a "C" or "F" clamp, a new set of front brake pads and a packet of brake caliper lubricant grease. A few compatible aftermarket front brake pads include the following with their part numbers: Wagner QC1414, Monroe DX1414, Motorcraft BR-1414, Raybestos ATD1414SV, Bendix D1414, Centric 105.14140, Motorcraft BRSD-1414 Bosch BC1414, Akebono ACT1414, Monroe CX1414, Power Stop # 16-1414 and Wagner ZD1414. |

||

|

|

||

Loosen 6 Lug Nuts |

Raise Vehicle |

Spin Off Lug Nuts |

| The first few steps

are to park the truck on a level surface, engage the emergency parking brake

and chock the rear wheels to prevent the vehicle from moving. If your F150 is equipped with lug nut covers or "hub caps" on the wheels, gently pry them off with a flathead screwdriver and set them aside in a safe place. Slightly loosen the 6 lug nuts with a tire iron by turning them counter clockwise. Raise the front of the vehicle with a floor jack and securely support it with at least two jack stands. (I prefer to work on one side of the vehicle at a time for extra safety.) |

||

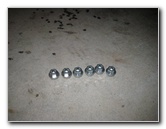

6 Lug Nuts Removed |

Pull Off Front Wheel |

Front Brake Caliper |

| Spin off the six

lug nuts and set them aside in a safe place before pulling off the front

wheel. Behind the wheel, you'll see the front brake caliper, rotor, bracket and suspension. Locate the two bolts on the back side of the caliper. |

||

Loosen Upper Caliper Bolt |

Loosen Lower 13mm Bolt |

Remove Upper Caliper Bolt |

| Loosen the upper

caliper bolt with a 13mm socket and ratcheting wrench by turning it

clockwise (as seen from the outside of the vehicle). Then loosen the lower 13mm caliper bolt. |

||

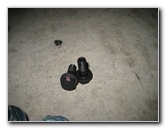

Remove Upper 13mm Bolt |

Two 13mm Bolts Removed |

Pull Off Front Brake Caliper |

| Remove both caliper

bolts and set them aside in a safe place. Carefully pull the front brake caliper off the old pads and out of the bracket. |

||

Rest Caliper On Suspension |

Remove Old Brake Pads |

Pull Out Old Inner Pad |

| Rest the brake

caliper on top of the rotor or hang it from the suspension spring with a

piece of twine or a bungee cord. Try to avoid stressing the rubber brake

fluid line. Pull the old outer and inner brake pads out of the bracket. |

||

|

|

||

Replace Anti-Rattle Clip |

Pull Out Caliper Slider Pin |

Lubricate Lower Pin |

|

If your set of new brake pads came with new metal pad abutment or "anti-rattle" clips, pull the old ones out of the top and bottom of the bracket before installing the new units. In order for the brake caliper to work properly, the upper and lower caliper slider pins need to be well lubricated. Pull the pins straight out of the bracket and apply a thin layer of brake parts lubricant grease to each one. Push the pins back in until their rubber dust boots snap back in to place. Thoroughly clean off the brake rotor, caliper bracket, brake caliper assembly and the lug nut studs with brake parts cleaner spray. Do not use compressed air or blow with your mouth to clean off the brake parts since breathing in brake dust can be harmful to your health. Brake dust can be carcinogenic (causes cancer) if inhaled.

To remove the existing rotors and install new ones, just remove the two bolts on the rear of the caliper bracket that attach it to the steering knuckle. Then loosen the old rotor with a rubber mallet, pull it off, and slide the new one in its place. |

||

Attach "C" Clamp |

Twist Off Brake Fluid Cap |

Compress Caliper Pistons |

| Attach the "C"

or "F"

clamp to the caliper using the back of an old brake pad to evenly distribute

the force across the two pistons. Move to the engine bay and twist off the brake fluid reservoir cap at the right rear area of the engine bay closest to the driver's seat. Removing the brake fluid reservoir cap will allow the brake fluid to more easily travel backwards through the system when you compress the pistons. Slowly turn the handle of the "F" clamp to compress the caliper pistons. You may need to reposition the "F" clamp to compress both pistons evenly. Check the fluid level in the reservoir repeatedly while compressing the pistons to make sure that it doesn't overflow. Clean up any spilled brake fluid immediately since it can damage painted surfaces. |

||

Replace Brake Fluid Cap |

Install New Outer Pad |

Install New Inner Pad |

| Replace the brake

fluid cap ASAP since brake fluid is hygroscopic (readily absorbs moisture). Apply a thin layer of brake caliper grease to any place where metal to metal contact takes place such as the outer rings of the two pistons. Do not apply lubricant to the friction surface of the new pads. Install the new brake pads in to the bracket. |

||

Push Pads Against Rotor |

Replace Brake Caliper |

Insert Upper Caliper Bolt |

| Push the new brake

pads flush against the rotor. Gently lower the brake caliper in to the bracket and over the new pads. If the caliper doesn't fit over the new pads, you may need to compress the caliper pistons back a bit further. |

||

Thread In Lower Bolt |

Tighten With 13mm Socket |

Tighten Lower Caliper Bolt |

| Line up the bolt

holes in the caliper with the corresponding holes in the caliper slider pins

within the bracket. Thread in the two caliper bolts by hand to prevent them from becoming cross threaded. Tighten the two caliper bolts by turning them counter clockwise with the 13mm socket and ratcheting wrench to just past hand tight or about 25 ft lbs of torque. The torque specification in the service manual for the 13mm front caliper bolts is 27 lb-ft (36 N*m). Double check that both caliper bolts are tight before continuing on to the next steps. |

||

Rubber Valve Cap |

Brake Fluid Bleeder Valve |

Replace Front Wheel |

If your brake pedal previously felt soft or spongy, the brake fluid may be contaminated with water or the brake lines may contain some air bubbles. It would be best to bleed the brake lines at this time in order to flush out the old fluid and replace it with fresh DOT3 brake fluid. For more on this topic, check out my Brake Line Fluid Bleeding With An Assistant DIY Guide or alternatively the Brake Line Fluid Bleeding With A Power Bleeder Guide. |

||

Spin On 6 Lug Nuts |

Slightly Tighten Lug Nuts |

Lower Truck With Jack |

| Replace the front

wheel and spin on the 6 lug nuts by hand to prevent them from becoming cross

threaded. Slightly tighten the lug nut with the tire iron. Lower the truck from the jack stands using the floor jack. |

||

Torque Lug Nuts |

Replace Lug Nut Cover |

Front Brake Pads Replaced |

|

Continue tightening the 6 lug nuts in a "criss cross" or "star" pattern to about 1/4 to 1/3 turn past hand tight. It would be best to use a torque wrench or an impact wrench with a torque stick to tighten the lug nuts to about 150 ft lbs of torque. Sit in the driver's seat of the vehicle and pump the brake pedal a few times to restore the brake line pressure. Check the brake fluid in the reservoir and verify that it is at the proper level. If it is low, add some DOT 3 fluid. Take the truck for a short test drive and then double check that the lug nuts are properly tightened. To break in your new front brake pads, just drive normally for the first few hundred miles while trying to avoid any hard or "panic" stops which may glaze over the new pads and cause them to be noisy and/or not perform as well. It's also a good idea to regularly check your driveway for drops of brake fluid which may indicate a leak, check the brake fluid level in the reservoir, and also verify that the lug nuts are still tight. For more,

check out my other

Ford F-150 Repair & Maintenance Guides. |

||

| If you found this guide to be helpful,

please consider making a small donation by clicking on the PayPal.com

"Donate" button located to the right of this paragraph. Thank you!

(Note: I am not a registered charity. Donations are not tax deductible.) |